Nylon Fiber

|

| Nylon Fiber |

The first synthetic fiber and the first fiber developed in the United States was nylon. As a means of diversification, the DuPont Company established a fundamental research program in 1928. Dr. Wallace H. Carothers, a high polymer expert, was hired by DuPont to lead a team of scientists. Starting with single molecules and building long molecular chains, the team created a variety of polymers. One of the team members discovered that a solution could be turned into a solid filament that was stable. The group was prompted to focus on textile fibers as a result of this. DuPont had developed polyamide fiber in a pilot plant by 1939. The nylon 6,6 fiber was first used in women's hosiery and was a huge success. The fiber was given the name nylon, but the reason for this choice is unknown. There were no laws defining generic names for fibers at the time.

Nylon had a unique set of properties compared to any other fiber available in the 1940s. It was tougher and more abrasion-resistant, with excellent elasticity and the ability to be heat-set. Pleats that remained in place became a reality. Gossamer-sheer fabrics were made durable and machine washable for the first time. Because of its high strength, lightweight, and chemical resistance, nylon is ideal for technical products like ropes, cords, sails, and parachutes.

Static buildup, poor hand, poor comfort in skin-contact fabrics, and low sunlight resistance became apparent as nylon entered more end-use markets. As issues arose, solutions were developed.

Production of Nylon

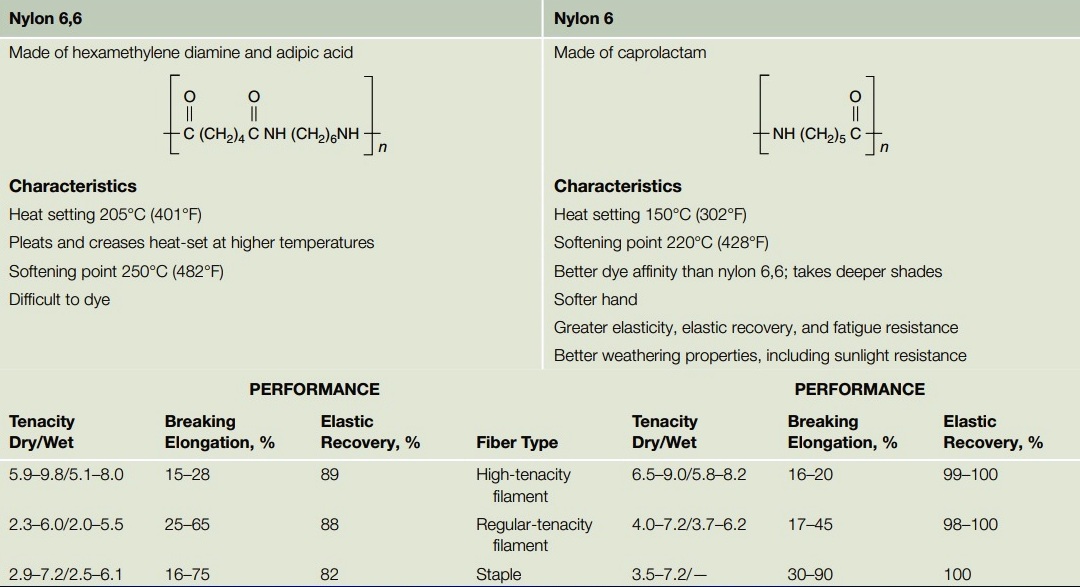

Nylon and polyamides are made from a variety of substances. The number of carbon atoms in the starting materials is indicated by the numbers after the word nylon. Nylon 6,6 is made up of six carbon atoms of hexamethylene diamine and six carbon atoms of adipic acid. While scientists in the United States worked on nylon 6,6, scientists in Germany worked on nylon 6. Caprolactam 4, a single six-carbon substance, is used to make it. Performance varies due to the different starting materials (Table 1).

|

| Table 1. Comparison of Nylon 6,6 and Nylon 6 |

Physical Structure of Nylon

The cross-section of regular nylon is round and uniform throughout the filament (Figure 1). The fibers appear to be fine glass rods under the microscope. Unless delustered or solution-dyed, fibers are transparent.

|

| Figure 1. Nylon Cross-sectional View (a), Longitudinal View (b) |

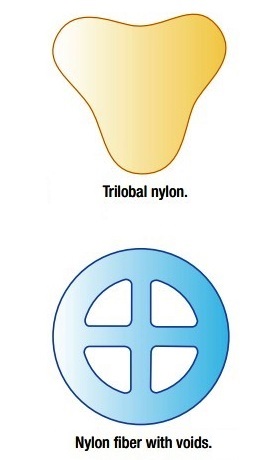

Initially, the uniformity of nylon filaments provided a distinct advantage over natural fibers, particularly silk. The perfect uniformity of nylon, on the other hand, resulted in woven fabrics with a dead, unappealing feel. Changing the shape of the fiber alleviates this condition. The shape of the spinneret hole is retained by nylon and other melt-spun fibers. As a result, where fiber shape influences performance, producers adjust the shape as needed. In nylon carpets, for example, trilobal fibers and square fibers with voids provide good soil-hiding properties (Figures 2).

|

| Trilobal and Square Fibers |

Chemical Composition and Molecular Arrangement of Nylon

Nylon is a synthetic fiber whose fiber-forming substance is any long-chain, synthetic polyamide in which less than 85 percent of the amide linkages are directly attached to two aromatic rings.

Nylons are polyamides with the elements carbon, oxygen, nitrogen, and hydrogen recurring in the amide groups. The chemical arrangement of nylons varies, which accounts for minor differences in some properties.

Nylon's molecular chains are long, straight chains of varying lengths with no side chains or cross-links. Cold-drawing aligns the chains, resulting in highly crystalline chains that are oriented lengthwise. The chain length of high-tenacity filaments is longer than that of regular nylon. Staple fibers are not cold-drawn after spinning and have lower degrees of crystallinity and tenacity than filament fibers.

Nylon is chemically related to the protein fibers silk and wool. Both have similar dye sites in dyeing, but nylon has much fewer dye sites than wool.

Properties of Nylon

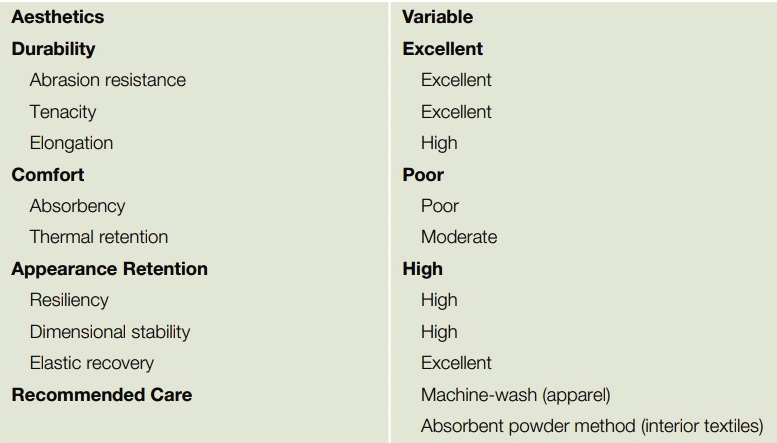

Table 2 summarises the performance of nylon in apparel and interior fabrics.

|

| Table 2. Performance of Nylon in Apparel and Interior Textiles |

Aesthetics

Nylon has changeable aesthetics that can be modified by choosing suitable fiber modifications, as well as yarn, fabric structure, or fabric finishes. Because of its smoothness, lightweight, and high strength, nylon has been very successful in hosiery and knitted fabrics such as tricots and jerseys. The luster of nylon can be chosen depending on the application it can be lustrous, semi-lustrous, or dull. The luster of trilobal nylons is pleasing.

The drape of nylon fabrics can vary greatly depending on the fiber and yarn size, as well as the fabric structure is chosen. High-drape fabrics are used in draperies, sheer lingerie overlays, and formalwear. Taffetas are stiff fabrics that are used for formalwear, parkas, interiors, and technical applications. Webbing for luggage handles and seat belts is an example of very stiff fabric.

Textures with smooth surfaces are popular. Texture can be changed by using spun yarns or changing the structure of the fabric. The filament yarn and compact structure are responsible for the smooth hand associated with nylon fabrics. Textured-yarn fabrics are bulkier.

Nonround fibers are commonly used in upholstery and carpets because round fibers magnify soil and appear dirty quickly. Trilobal, pentalobal, and voided fibers conceal soil even if the product is soiled, the soil is not visible. Furthermore, the fibers' voids and flat sides scatter light, hide soil, and closely mimic the matte luster of wool and other natural fibers (see Figures 2).

Durability

Nylon is highly durable. The tenacity and abrasion resistance is outstanding. The degree of elongation is high. High-tenacity fibers are used in seatbelts, ballistic fabric, tire cords, and other technical applications. Fibers with regular tenacity and staples are used in apparel and interior textiles. High-tenacity (HT) fibers are stronger than regular-tenacity fibers but have less elongation. High-tenacity fibers are drawn to a greater extent than regular-tenacity fibers during production, making the HT fibers more crystalline and oriented. High-strength nylon fibers are used in technical products such as towropes, where high strength and low elongation are required.

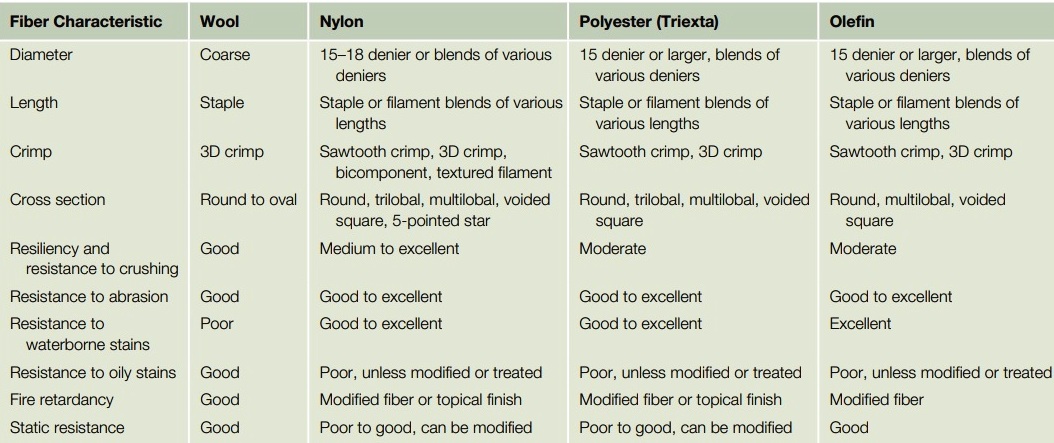

Nylon has excellent abrasion resistance in addition to excellent strength and elongation. Carpet is a common application for nylon (Table 3). A good carpet is long-lasting, resilient, and resistant to pilling, shedding, fading, traffic, abrasion, soil, and stains. Many of these requirements are met or exceeded by nylon. Because of its excellent durability and high resiliency, nylon is also prominent in pile upholstery fabrics.

|

| Table 3. Comparison of Wool and Synthetic Carpet Fibers |

Because of these characteristics, nylon is an excellent fiber for women's hosiery and tights. For pantyhose and tights, no other fiber has been able to compete with nylon. Nylon's high elongation and excellent elastic recovery account for its outstanding performance in this application. Tights and hosiery have a high degree of elongation; nylon recovers better than other fibers after high elongation. Nylon can also be heat-set to keep its shape while being worn. Filament hosiery develops runs when the fine yarns break and the knit loop no longer holds together. Sheer hosiery is less long-lasting than opaque tights. Microfiber nylon tights are warmer and softer than regular-sized apparel fiber tights.

Lining fabrics in some coats and jackets are made of nylon. Nylon linings are more durable, but they are more expensive due to the greater difficulty in sewing and higher costs when compared to acetate fabrics. Nylon is not a long-lasting window treatment fabric because it is weakened by sunlight. Sunlight- or ultraviolet-resistant modified fibers are used in sheer curtains, draperies, car interiors, seatbelts, and other high-exposure technical applications.

Comfort

Nylon is uncomfortably stiff. It is not very absorbent. Despite having the highest absorbency of any synthetic fiber (4.0 percent to 4.5 percent for nylon 6,6 and 2.8 percent to 5.0 percent for nylon 6), nylon is not as comfortable to wear as natural fibers.

Compact filament nylon yarns were initially used in woven sports shirts for men. When wet from perspiration, the shirts became transparent and felt clammy, especially in hot, humid weather. Textured and spun yarns used in knit fabrics today result in more comfortable shirts. Knit nylon fabrics are more comfortable than woven nylon fabrics because heat and moisture escape more easily through the fabric's additional air spaces. Polymer modifications make nylon clothing more comfortable. Thermal underwear, actionwear, footwear, and accessories all use a hydrophilic fiber with improved absorbency and wicking.

The same factors which make nylon uncomfortable in one set of conditions make it convenient in another. Nylon has low thermal conductivity. It's commonly used to make wind and water-resistant jackets, parkas, tents, and umbrellas. The smooth, straight fibers pack tightly together in yarns that can be woven into a dense fabric with little space for wind or water to penetrate.

Another disadvantage of poor absorbency is the generation of electrostatic discharge in low humidity due to friction. Antistatic nylon modifications, antistatic finishes, or blends with high-absorbency, low-static fibers can help to overcome this disadvantage.

Static electricity causes issues with comfort, soiling, and use. Antistatic fiber and finish modifications are common carpet modifications. To reduce static in carpets, small amounts of metallic and carbon fibers are sometimes used. Lining fabrics and slips are made with antistatic nylon.

Nylon is one of the lightest fibers on the market, with a specific gravity of 1.14. In comparison to polyester, nylon produces 21% more yardage per pound of fabric. This lighter weight translates to lighter products and lower costs for transporting and finishing fabrics. Nylon's lightweight and excellent durability make it ideal for actionwear and sports gear.

Appearance Retention

Nylon fabrics have a high appearance retention rating. Because of the heat-setting process, nylon is extremely durable. Permanent pleats, creases, and engraved designs are all created using the same method. Before being incorporated into the carpet, nylon carpet yarns are heat-set. Heat setting enhances the excellent compressional resiliency of nylon fibers in pile yarns. Carpet fibers' compressional resiliency is their ability to spring back to their original height after being bent or otherwise deformed. Traffic lanes do not form quickly. Furthermore, depressions caused by heavy furniture are less likely to be permanent. Steaming these areas can help to reduce the appearance of heavy furniture marks. Because higher-denier fibers have better compressional resiliency and appearance retention, most carpet fibers are made in a high denier, often 15 or greater.

Dimensional stability is outstanding. Nylon resists shrinkage due to the heat setting and the fact that the low-absorbency fiber is unaffected by water. Elastic recovery is fantastic. Nylon recovers completely from 8% stretch; no other fiber does. It recovers 91 percent of its elongation at 16 percent elongation. Nylon is an excellent fiber for hosiery, ski pants, swimsuits, tights, and other actionwear because of this property. Nylon does not wrinkle easily, is stable, and has excellent elastic recovery, so it maintains its appearance while in use.

For areas where fading, particularly from exposure to sunlight, is a concern, solution-dyed and sunlight-resistant carpet fibers are available. These carpets are designed specifically for low-priced contract/commercial markets as well as automotive interiors. Life vests, Flags, and other technical applications make use of ultraviolet-resistant nylon fiber.

Care

Nylon clothing may be cleaned and dried in the washing machine. The absorbent powder approach can be used to clean interior fabrics. Nylon pioneered the notion of easy-care clothing. During usage and care, nylon textiles maintain their look and form.

Nylon's wet strength is 80% to 90% of its dry strength. Wet elongation slightly increases. When nylon is wet, it swells somewhat. Compare the swelling of various fibers: nylon, 14%; cotton, 40% to 45%; and viscose-rayon, 80% to 110 percent. These characteristics add significantly to nylon's reputation as an easy-to-care-for material.

Warm wash water, mild agitation, and gentle spin cycles are ideal for minimizing wrinkling. Some textiles may wrinkle as a result of being washed in hot water. Hot wash water can cause permanent wrinkles, but it can also help eliminate grease and oily stains.

Nylon is a color thief. Colors from other textiles or dirt in the wash water are picked up by white and light-colored nylon materials. A crimson sock that fades into the wash water of a batch of whites may stain the white nylon materials, making them tough to remove. The use of chlorine bleach over an extended period may cause white nylon to yellow. By following proper laundry processes, you may avoid discolored nylon as well as greyed or yellowed nylon.

Nylon dries fast because of its limited absorbency. Short drying periods are required. Nylon is sensitive to overdrying and dryers set on high heat. The melted and fused result of a nylon garment dried in an overheated gas dryer with socks of varying fiber content is shown in Figure 3.

|

| Figure 3. The Melted and Fused Remains of Nylon Garments |

Nylon is prone to static electricity, especially when the air is dry, thus a fabric softener should be used while cleaning. To avoid glazing, nylon should be pressed or ironed at a low temperature of 270F to 300F. Home ironing temperatures are insufficient to permanently press seams, creases, and pleats in clothes or to remove wrinkles caused by washing.

Nylon's chemical resistance is typically good. Nylon is resistant to alkali and chlorine bleaches, although it is harmed by strong acids. Pollutants in the atmosphere can harm nylon or cause issues with particular colors used with nylon. When some acids are printed on cloth, they produce a puckered look. Formic acid and phenol dissolve nylon.

Nylon is resistant to insect and fungal attacks. Food soil on carpets, on the other hand, may attract insects. Nylon has a low UV resistance. Bright fibers are more resistant to sunlight than delustered fibers because the damaging energy is reflected rather than absorbed. Nylon modifications that are resistant to sunlight are available.

Carpet soiling can be a major issue. Carpet soiling is related to fiber cross-section, carpet color, and fiber opacity/translucence. Soil is magnified in round cross-sections. Soil is hidden by non-round cross-sections such as trilobal, pentalobal, and voided (see Figures 2). Carpet fibers with soil-resistant modifications reduce soil adherence and permanent staining. Furthermore, many carpets now incorporate soil-resistant fiber modifications as well as soil-resistant finishes

Sustainability of Nylon

Nylon has a high resistance to natural degradation and does not degrade quickly. It is resistant to mold, mildew, rot, and a variety of chemicals. Although most nylon is susceptible to sunlight damage, the damage does not occur quickly enough to minimize nylon product disposal issues. Because nylon is made from petrochemicals, there are concerns about the petrochemical industry's political, social, and environmental impact: drilling in sensitive areas, pipelines and other transportation issues, oil spills, the refinement and production of the chemicals from which nylon is made, and the use and disposal of hazardous chemicals. The manufacture of nylon requires more energy than the manufacture of polyester or cotton. Nitrous oxide, a greenhouse gas, is emitted by nylon manufacturing plants.

To clean the fiber during the processing of nylon from raw fiber to finished product, few, if any, chemicals are used. This is because, unlike natural fibers, nylon and other synthetic fibers are not contaminated with soil and other materials such as leaf bits during production. Because nylon is a melt-spun fiber, no chemical bath residue must be rinsed from the fiber, and no solvents, such as those used with wet- or dry-spun fibers, must be reclaimed. Furthermore, less water, salt, and acid are used to dye the fiber. Excess dye from nylon fabrics is removed with less water than some common dyes used on natural and regenerated cellulose fibers. Because nylon fiber can be engineered for specific end uses, chemical finishes are rarely required to improve consumer satisfaction with nylon products. As a result, once nylon fiber is produced, further processing of nylon has a negligible environmental impact.

Nylon is made from waste materials from oil refineries. The raw materials for nylon were previously considered waste products. Recycling nylon is a viable alternative to disposal. The presence of other materials added to the melt in the production of the original material, as well as the wide variety of nylon polymers on the market, are two issues with recycling nylon.

A cost-effective commercial carpet recycling program converts nylon carpet fiber into caprolactam (a nylon 6 raw material). Other recycling programs for nylon carpet fiber shave the fiber from the surface of the carpet and mix it with plastic and concrete. Recycled picnic tables and poured concrete foundations are made from lightweight and durable composite materials of fiber and plastic or fiber and concrete. Unfortunately, not all nylon carpet that is discarded is recycled. In some cases, this is since a significant portion of the nylon used in carpet is applied to olefin or other backing materials, which complicates recycling. Because of the dye, declustering, and soil- and stain-resistant compounds present in the most nylon carpet pile, the additives used to improve the performance of nylon carpet make recycling more difficult.

Uses of Nylon

Nylon is one of the most widely known fibers. Carpets are nylon's most important application. Tufted carpets are an excellent end-use for nylon due to their aesthetically pleasing appearance, durability, appearance retention, and ability to be cleaned in place. The combination of nylon fiber and the tufting process results in relatively low-cost and highly serviceable carpeting, which contributes to carpeting's widespread use in both residential and commercial buildings.

A second important application for nylon is in clothing. Nylon lingerie is appealing and long-lasting, with good appearance retention and ease of care. Nylon is commonly used to make panties, bras, nightgowns, pajamas, and lightweight robes.

Women's tights and sheer hosiery are two important applications for nylon. No other fiber possesses the combination of properties that makes it ideal for that application. Instead of a heavier-denier yarn or monofilament, very sheer hosiery is often 12 to 15 denier. Hosiery yarns can be plain or textured, regular or microdenier in size, and monofilament or multifilament stretch nylon.

Nylon is sometimes used to make short or knee-high socks. They are frequently nylon blends with cotton or acrylic. Nylon adds strength as well as stretch. Nylon is commonly used in the toe and heel of socks to increase wear life. Other end uses for nylon include active sportswear and actionwear where comfort stretch is important, as well as leotards, tights, swimsuits, and ski wear. In cool and windy weather, nylon-taffeta windbreakers and parkas are popular. Nylon can be used as a lining fabric for jackets and coats.

Some performance nylon fibers have been modified to have a cotton-like hand with improved pilling resistance, and they are used in the inner layers of workwear, mountaineering apparel, and hunting apparel. Other nylons for outdoor use and hunting apparel have been altered to be stain- and tear-resistant, quiet (causing little rustling or other noise that might frighten away game animals), quick-drying, and warm. These fabrics are used in the outer layers of workwear, as well as hunting and hiking clothing. Supplex ™ is microfiber nylon that has been modified to be softer, suppler, and less bulky than regular nylon, allowing for more freedom of movement in outerwear, beachwear, and actionwear. Supplex ™ is windproof, water repellent, breathable, and long-lasting.

Nylon has a wide range of technical applications. Nylon is used for the tire cord that runs from rim to rim over the curve of some radial tires, but polyester, heat-resistant aramid, and steel are substituting nylon due to its flat-spot tendency. Flat spotting happens after a car has been parked for a while and a flattened spot forms on the tire. For the first mile or so, the ride is bumpy as the tire recovers from flattening.

The average car consumes 25 pounds of fiber, the majority of which is most likely nylon. Upholstery fabric (called body cloth), carpet for the interior, door and visor trims, trunk lining, seatbelt webbing, and headliners on interior roofs are all examples of car interiors that use nylon. Some are modified to be resistant to sunlight, heat, or to have a high tenacity. Nylon is also used in clutch pads, brake linings, yarns for reinforcing radiator hoses and other hoses, and airbags.

Parachute fabric, glider tow ropes, cords and harnesses, ropes and cordage, fishing nets, conveyor belts, mail bags, consumer uses, webbings, leisure, and sporting goods fabric are some of the other technical applications. Umbrellas, toothbrush and hairbrush bristles, clotheslines, paintbrushes, and luggage are all examples of consumer applications. Tents, spinnaker sails, fishing lines and nets, sleeping bags, racket strings, backpacks, and duffle bags are examples of sporting goods. Soft luggage, book bags, backpacks, camera bags, golf bags, hunting gear, and horse blankets are examples of leisure goods.

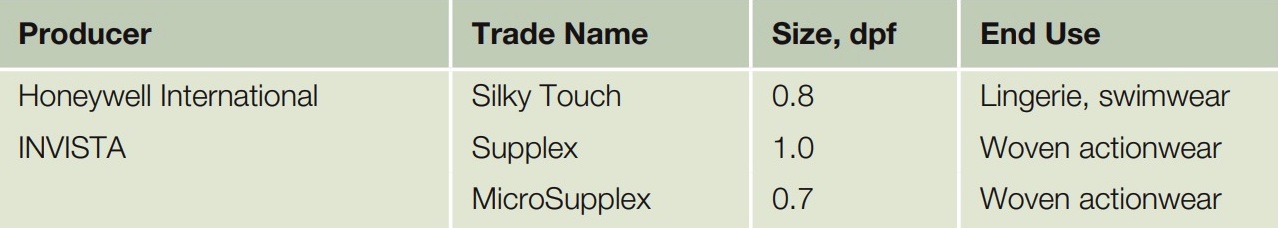

Nylon microfibers are used in clothing and interior design. These fibers are 26% to 36% softer than regular nylon fibers and have a denier of 0.7 to 1.0 dpf, compared to a denier of 2.0 dpf for regular nylon. Micro nylons are used in a wide range of applications. Water-repellent, wind- and wear-resistant, vapor-permeable, and comfortable fibers. They are used in 100% nylon formations as well as blends with natural fibers such as wool and cotton (Table 4).

|

| Table 4. Nylon Microfibers |

Types and Kinds of Nylon

It has been said that whenever a new need arose, a new type of nylon was created to meet that need. As a result, there are numerous types of nylon that are identified by trademarks.

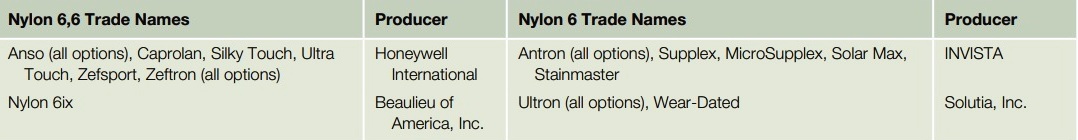

Table 5 depicts a variety of nylon modifications. Table 6 lists the trade names of several nylon producers. Appendix C contains a list of additional nylon trade names.

|

| Table 5. Types and Kinds of Nylon |

|

| Table 6. Some Trade Names and Producers |

.png)

0 comments:

Post a Comment